Multi Disciplinary Engineering

Multi Disciplinary Engineering

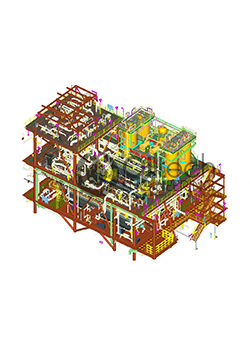

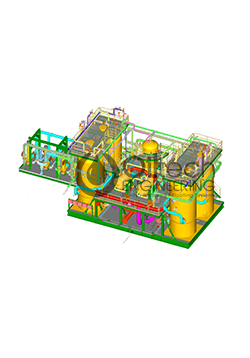

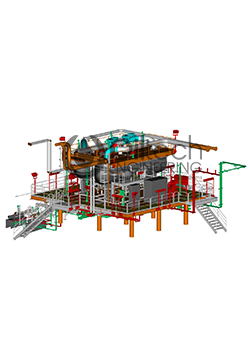

Our teams provide engineering solutions across the asset life cycle from conceptual studies and FEED to detailed engineering for energy, marine and industrial sectors.

Working with you to understand your requirements, and using the learnings of hundreds of capital projects and our extensive operations portfolio, we will bring unique insights to your project. Challenging the norm, drilling into key cost drivers, and applying value-adding engineering techniques to deliver the best solutions in line with your investment strategy. Everything we do is focused on safe, fit-for-purpose design and specification, which ensures constructability and operability.

When we execute a front-end engineering design (FEED), we are committed to providing security of quality, cost and schedule, along with safe designs which are implementable and operable. The knowledge held by our global teams enables us to produce front-end solutions which reduce CAPEX, OPEX and schedule, while enhancing safety and operability.

With us, delivery is always assured.

- Process Simulation & Process Optimization (Typical tool: HYSYS)

- Flow Sheet development with Heat and Material balances

- Preparation of PFD and P&ID

- Specifications for Process Equipment and Instruments

- Basic Engineering Package for Process Units, Utilities

- Conceptual Top-side Layout

- Process Control Philosophy

- Process Shutdown Philosophy (Normal & Emergency)

- Cause and Effect Diagram

- Assistance for HAZOP Studies

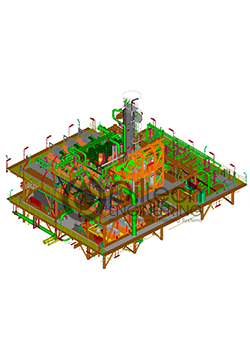

- Detail Layout for Overall Topside

- Equipment Layout Drawings

- Piping Materials Specifications

- Specifications for Specialty Items

- Piping General Arrangement (GA)

- Piping Isometrics

- Pipe Stress Analysis (Typical tool: CAESAR II).

- Pipe Support Design

- Material Take Off (MTO)

- Selecting and specifying:

- Compressors, Blowers & Fans-Pumps

- Turbines & Engines

- Preparation of Data Sheets and Purchase Specifications

- Requisitioning and Review of Vendor Drawings/Specifications.

- Vibration Analysis

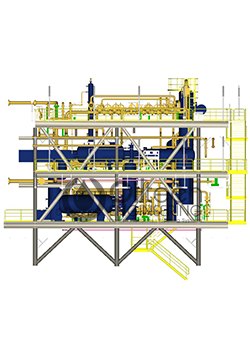

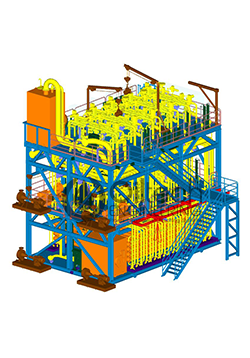

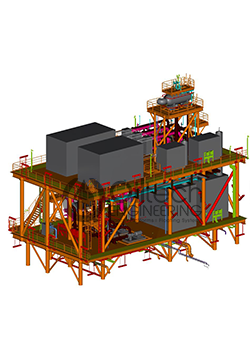

- Design, modeling and analysis- offshore structures

- Structural Analysis (Typical tools: SACS, GT Strudl, FEA) – In-place- In-service- Transportation-Heavy lift

- Design of modular structures, integrated units, multilevel units

- Structural Drafting ( AutoCAD, CAD Worx), 3D Modeling

- Bill of Quantities and material specifications

- Local and Global strength analysis, hydrodynamic – model analysis

- Load outs, float off, float over analysis

- Demolition Engineering

- Vessel Condition Evaluation

- Remaining Life Extension

- Hull Under Deck Strengthening – Analysis and Design

- Marine Conversion

- Accommodation & Helideck

- Sewage System

- Water Maker System

- Slop Tanks; Open & Closed Drains

- Fire Water System

- Marine Conversion

- Foam System

- Fire & Gas

- Tank Systems

- Relocation of Suctions & Vents

- Tanker Offloading System

- Produced Water Discharge

- Sea Water Lift Pumps

- Fresh Water, DM Water, Service Water Systems

- Winches

- Instrumentation Design Basis

- Control Philosophy and Specifications

- Detailed Engineering and Specifications for:

- Distributed Control Systems

- Programmable Logic Controllers

- Emergency Shut Down Systems

- Fire and Gas Detection System Philosophy and Specification

- Sizing of Control Valves, Flow Elements, Safety Valves, etc.

- Data Sheets/Specifications for Instruments, Control Valves, Safety Relief Valves etc.

- Instrument Bulk Material Take-off

- Cable Selection and Scheduling

- Control Room Design including Panel, Console Layouts

- Cable Tray Layout and Conduit Routing

- Instrument Installation Hook-ups

- Instrument Loop Diagrams

- Instrument Indexing

- Review of Vendor Drawings and Documents

- Power System Studies:

- Load Flow

- Short Circuit

- Motor Starting etc

- Power Generation and System Design

- Single Line Diagrams (SLDs)- ETAP

- Protection Relay Coordination Diagram

- Cable System Design, Scheduling and Take – off

- Lighting System Design

- Uninterrupted Power Supplies (UPS) – Design and- Specification

- Cable & Equipment layout

- Electrical Terminal Connection Diagram

- Requisitioning and Review of Vendor Drawings/Specifications

- HSE PHILOSOPHY

- HAZARDOUS AREA CLASSIFICATION

- ACTIVE FIRE PROTECTION

- FIRE ZONE DEFINITION

- FIRE WATER DEMAND CALCULATION

- FIRE WATER PUMP SIZING

- DELUGE P&IDs

- FIRE FIGHTING & LIFE SAVING EQUIPMENT LAYOUTS

- PASSIVE FIRE PROTECTION

- SAFETY STUDIES SCOPE OF WORK & METHODOLOGY

- TECHNICAL SPECIFICATIONS

- DATASHEETS

- KEY SAFETY STUDIES

- QUALITATIVE(HAZOP & HAZID)

- QUANTITATIVE(SIL, QRA, FERA , SCE-I & PS, COLD VENT GAS DISPERSION, FLARE RADIATION Studies)

- OTHERS

- NOISE & VIBRATION

- FIRE WATER HYDRAULICS & SURGE ANALYSIS